- January 01, 2026

Solving India’s Packaging Sourcing Challenge for Global Enterprises

Global enterprises manufacturing and selling in India—across industrial, automotive, consumer, and engineering sectors—face a common but under-addressed challenge: finding the right packaging suppliers at scale.

Companies such as GE, BMW, and many other multinational corporations operate large India offices, sourcing hubs, and manufacturing plants. While India offers scale, cost advantage, and depth of manufacturing, identifying the right packaging vendors remains surprisingly difficult.

Packaging is no longer a tactical purchase—it is a strategic supply-chain input that directly impacts cost, sustainability, delivery timelines, and risk.

Why Packaging Procurement Is Uniquely Complex

Packaging spans multiple, highly specialised sub-categories:

-

Corrugated boxes & heavy-duty industrial packaging

-

Flexible packaging (films, laminates, pouches)

-

Rigid plastics and injection-moulded components

-

Wooden pallets, crates, and export-grade packaging

-

Sustainable, recyclable, and ESG-compliant materials

-

Custom-engineered packaging for machinery and components

Each category requires specific capabilities, tooling, certifications, volume-handling capacity, and logistics readiness.

For global enterprises, packaging must also align with:

-

Global quality standards

-

Sustainability & ESG commitments

-

Export and compliance requirements

Yet most procurement teams still rely on manual discovery methods.

The India Paradox: Capacity Without Discoverability

India has thousands of capable packaging MSMEs across clusters such as:

-

NCR, Pune, Chennai, Bengaluru – industrial & automotive packaging

-

Ahmedabad, Vadodara – plastics and rigid packaging

-

Mumbai, Hyderabad – flexible packaging

-

Tier-2 and Tier-3 cities – cost-efficient, scalable capacity

But capacity does not equal visibility.

Procurement teams struggle to answer:

-

Who can handle my volumes and specifications?

-

Who is closest to my manufacturing location?

-

Who meets global compliance and sustainability norms?

-

Who has executed similar enterprise-grade requirements before?

This discovery gap results in sub-optimal suppliers, higher costs, and supply risk.

Enterprise-Grade Compliance & Documentation

Venqon structures supplier onboarding around:

-

Quality and compliance certifications

-

Environmental & sustainability credentials

-

Legal, factory, and audit documentation

Procurement teams gain confidence, governance, and traceability from day one.

Multi-Vendor Discovery & Risk Diversification

Venqon enables enterprises to:

-

Identify multiple qualified suppliers simultaneously

-

Create backup sourcing plans across locations

-

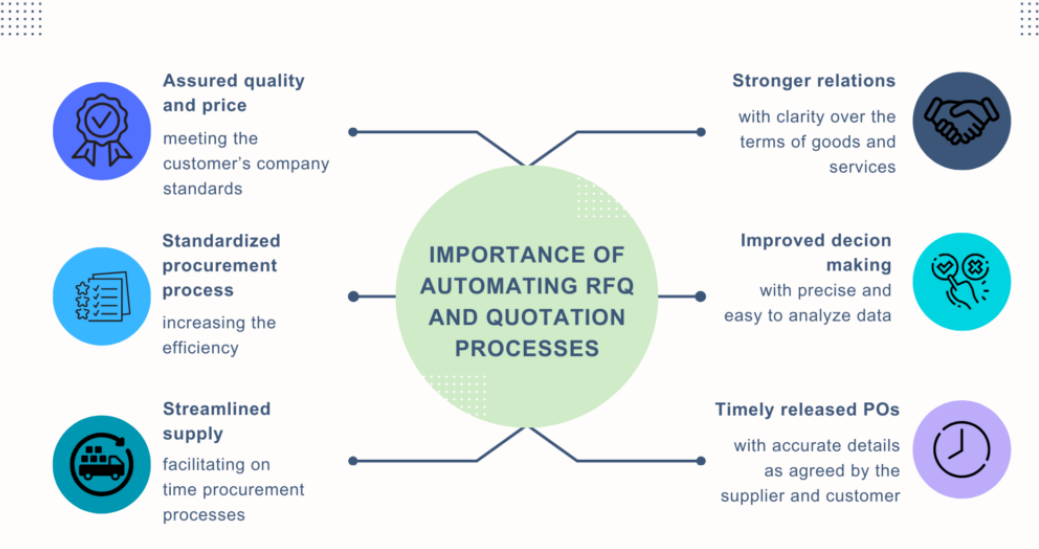

Run competitive RFQs without manual effort

This significantly improves supply continuity and negotiation power.

Why Existing Solutions Fall Short

Most procurement tools focus on:

-

ERP transactions

-

Purchase order management

-

Spend analytics

They do not solve the upstream challenge of finding the right suppliers.

Marketplaces focus on seller listings. Consultants offer manual shortlists.

None deliver AI-driven, requirement-specific vendor identification at enterprise scale.

Venqon is different because:

-

It focuses exclusively on vendor discovery and RFQ matching

-

It is designed for large enterprises and MNCs

-

Suppliers are evaluated as capability profiles, not directory listings

There is currently no other platform in India addressing this problem with comparable depth.

Strategic Impact for Global Enterprises

Using Venqon, enterprises can:

-

Reduce supplier discovery time from weeks to days

-

Access high-quality MSME suppliers beyond existing panels

-

Lower total packaging costs through better fit and competition

-

Improve supply-chain resilience

-

Align sourcing with sustainability and ESG objectives

Packaging moves from a cost centre to a strategic advantage.

Conclusion

India has the packaging capacity global enterprises need.

What’s missing is intelligent, trusted discovery.

Venqon bridges this gap—enabling enterprises to identify, evaluate, and engage the most suitable packaging suppliers by location, capability, compliance, and scale.

If you are an MNC or large enterprise sourcing packaging in India, Venqon is not optional—it is strategic.

Visit Venqon.com to explore enterprise packaging sourcing

Request a pilot to identify suppliers near your manufacturing plants

Build a resilient, future-ready packaging supply chain with Venqon